PRODUCTION PLANNING

WHAT IS PLATE ASSIGNMENT?

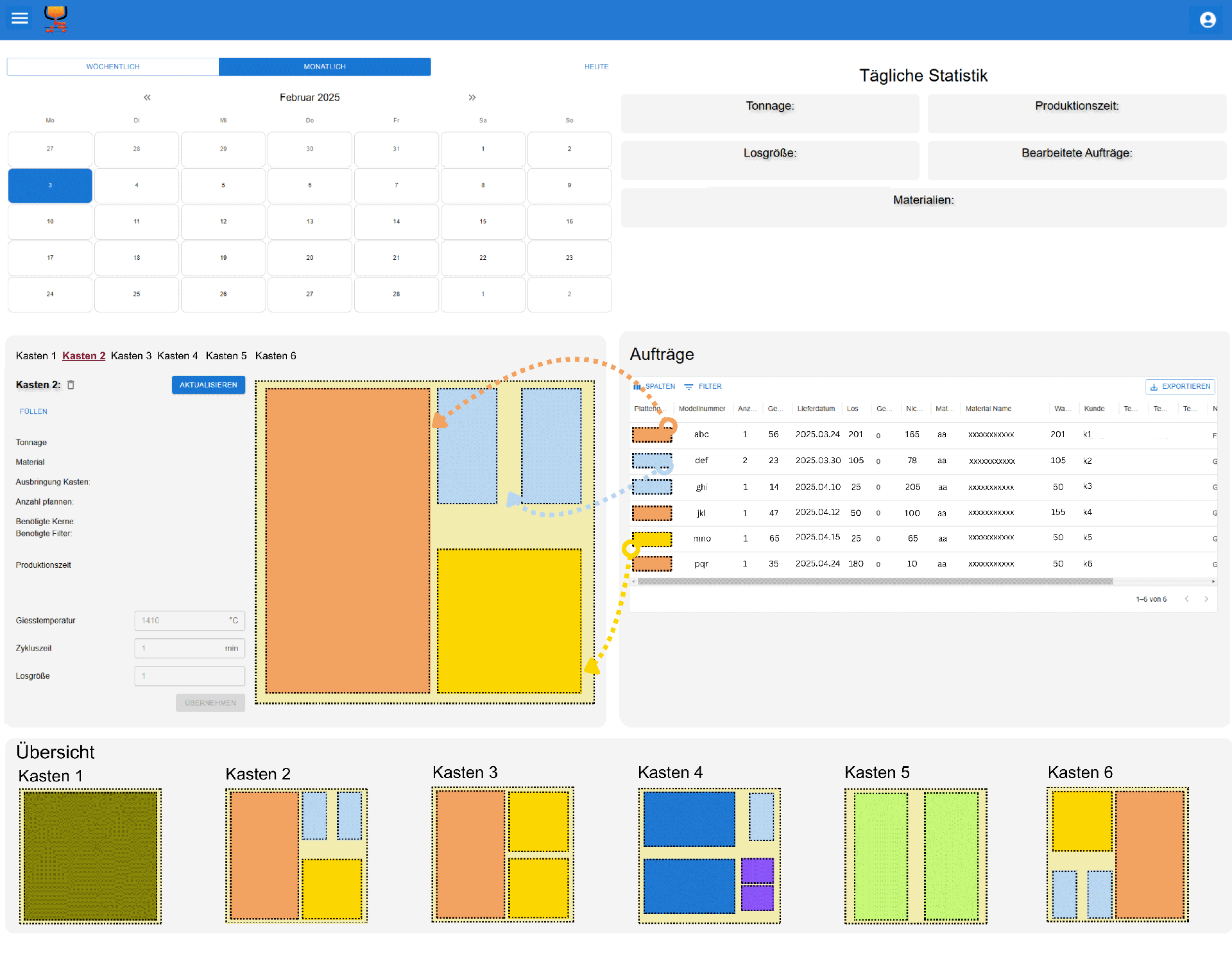

Plate assignment refers to the strategic process of assigning the correct plates for production in a foundry. Traditional methods often rely on manual planning, which is prone to errors and inefficiencies. Casculate’s data-driven production planning tool automates and optimizes this process, ensuring the best use of materials and production capacity.

Intelligent Plate Assignment

Our system assigns the most suitable plates based on:

- Material properties

- Plate size and type

- Order priority

-

Machine availability

Real-Time Scheduling and Monitoring

- Dynamic scheduling based on real-time production data

- Adjusts schedules automatically in response to production changes or machine downtime

-

Tracks material availability and production flow

Smart Visualization

- Different plate sizes represented with color coding

- Real-time display of available plates and their combinations

- Data presented through graphs and charts for quick decision-making

Drag-and-Drop Interface

- Easy-to-use visual interface

- Planners can assign plates using drag-and-drop

-

Invalid configurations are automatically blocked, reducing human error